X-ray diffraction:

Material characterization and detection

Material characterization and detection

Overview

My team is a member of the Department of Homeland Security Science and Technology's ALERT (Awareness and Localization of Explosive Related Threats) Center of Excellence (COE). Together, we are working toward improved safety and a more streamlined airport security experience.

The detection of contraband and explosives concealed within a large volume of confounding items is a challenging task. X-ray based imaging has been central to this effort for nearly the last two decades, but conventional transmission-based methods lack the material specificity required to accurately detect the target items of interest. X-ray diffraction tomography (XRDT) has the potential to dramatically improve the sensitivity and specificity of X-ray-based explosives detection systems because of its ability to identify concealed materials based on their microscopic atomic and/or molecular structures. While this sensitivity to molecular composition is necessary for accurately assessing a host of benign and threat materials, it may at times be too sensitive: the details of the measured X-ray diffraction scatter signatures can depend on a variety of factors relating to environmental history and conditions. In this project, we are quantifying, modeling, and overcoming these challenges in order to help develop these next-generation X-ray detection technologies.

To address these challenges, we are working in three main areas:

- Creating a shareable database (contact joel.greenberg*at*duke.edu for access) In order to understand how to build systems and algorithms to detect threats using XRD, we first need to understand their signatures (including the variability of the signatures) in this space. We focus here on building a database of XRD signals that include multiple realizations (e.g. different orientations, grain sizes, processing history, etc.) of a broad range of objects/materials relevant to aviation security.

- Development of novel simulation tools By combining our database of XRD signatures with a model of the physics (both of light-matter interactions in the object and of source/detector behavior) and geometry, we can generate realistic data for various measurement architectures.

- Analyzing the performance of XRDT systems Analyzing the impact of texturing on XRDT imaging performance and studying new ways to measure and process the data to mitigate the deleterious effects of texturing.

For more than 100 years, the fundamental science behind XRD has been developed and applied to understanding the structure and properties of materials. It is well-known that the XRD signal depends on the molecular structure of the material at the microscopic scale. Because of this, XRD yields a signature for distinguishing materials from one another (i.e. performing material identification). However, details in the microscopic structure of the material can impact the XRD signature. A particular example of this is known as texturing, in which the type, degree, and relative orientation of the crystal structure of a sample impacts the details of the XRD scatter signal. While these details are useful for investigating the properties of a known material, they pose challenges (and therefore usually ignored) in the case of performing material identification and/or threat detection of an unknown material.

A variety of XRD databases exist; however, they are of limited value to aviation security for several reasons. First, they typically involve measurements made with carefully-prepared powders samples (as opposed to solid or highly crystalline samples), which guarantees that texturing is absent. Furthermore, they typically only cover specific classes of materials (e.g. biomolecules or metal alloys) which do not adequately represent many common objects found in luggage (such as toothpaste, cheese, paper, water, etc.). Finally, existing databases usually include only a few instantiations for each unique material, and do not included various orientations of textured materials. Without an adequate understanding of the inherent variability of the XRD signatures, one cannot evaluate the performance of any real-world XRDT system.

In addition, the conventional XRD measurements are made using a standard X-ray diffractometer operated in reflection mode at a single, low X-ray energy to record the scatter form factors. For aviation security applications, however, measurements are made in transmission mode and require high energies (20-180 keV) in order to penetrate bags. Because the scatter cross section changes as a function of energy and angle, it is important to record the complete energy- and angle-dependent scatter cross sections. While a synchrotron system has recently been built to measure the angle and energy dependent XRD signal over a limited range of energies, this method is hardly practical for use in real labs and too expensive to use to generate large databases worth of data. Without the aforementioned databases (which include stream of commerce materials measured at appropriate energies and including material variations), it is extremely difficult to design XRDT systems or develop appropriate detection algorithms, as material signatures and their associated variability are central to these tasks. We have therefore built a comprehensive database relevant to threat detection in order to improve the performance of existing systems and properly evaluate the performance of future scanners.

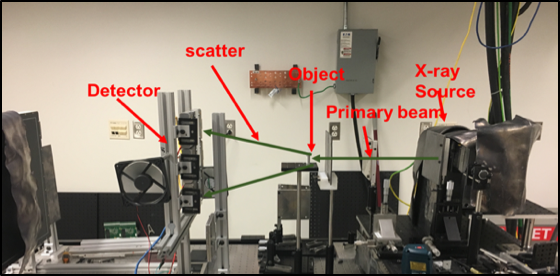

Energy-dispersive Laue (ED Laue) Diffractometer: To generate a database relevant to aviation security needs, we have built an energy-dispersive Laue diffractometer. This testbed X-ray system is capable of collecting the XRD signal over a large range of energies (20 - 160 keV) and angles (deflection angles between 1-30 degrees). The system consists of an X-ray source; collimation optics to create a pencil beam; a sample object (which can be rotated and/or translated); and an effectively 2D energy sensitive detector array. This allows us to collect the 3D scatter data (i.e., scatter in theta and phi and energy). All components are COTS, and a high SNR scan of a sample can take between 5 and 45 minutes, depending on the sample.

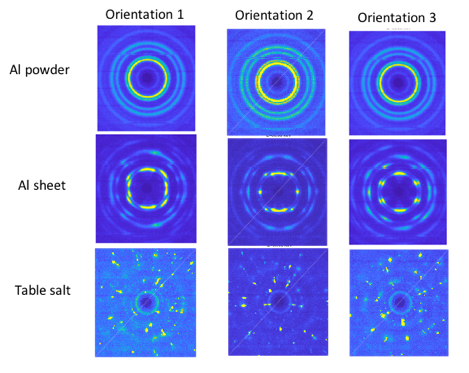

ED Laue database Using the ED Laue system, we have scanned over 50 distinct materials and organized the measurement results into a searchable database that can be downloaded by contacting joel*dot*greenberg*at*duke*dot*edu . Each material was placed in the system with multiple orientations, and many in multiple forms (e.g. sheet, powder, different vendors, different processing histories). We find that fine powders, such as Al, give symmetric rings with no texturing at all energies and orientations. Aluminum sheet, however, has textured rings that vary around the ring (azimuthally) and depend on the orientation of the sample relative to the beam, but have no variation or structure in energy. For polycrystalline powders with large grain sizes, such as Salt in a shaker, scatter only arises at particular angles and energies and depends sensitively on the configuration of the individual polycrystalline grains. This indicates the challenges associated with XRDT on highly textured materials, as both collecting and interpreting the signal can be very challenging (compared to an untextured material).

Energy- and angle-dispersive X-ray diffraction database by Joel Greenberg is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License

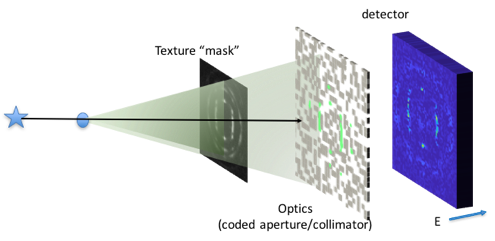

We have previously developed both a fast, deterministic, first-order scatter model of XRD and Compton scatter as well as a Monte Carlo tool (including all relevant physics) for simulating scatter from untextured materials. Because the details of the texture pattern are impossible to predict ab initio but the details of their structure are critical to system performance, we implement an empirical approach to XRD texture modeling in which we use the ED Laue scatter measurements (i.e. the elements of our database) as texture “masks” in the simulation system. By modulating the scatter at specific energies and angles in the simulation, we can create realistic scatter distributions for materials whose texturing ranges from negligible to highly textured. We have validated our scatter simulation against experimental data. The simulation enables us to simulate arbitrary system architectures by changing component parameters (e.g., detector type), geometry, optics (including coded apertures and collimators) and for objects with spatial and material descriptions limited only by the extent of our material databases. The general description of this method is shown below.

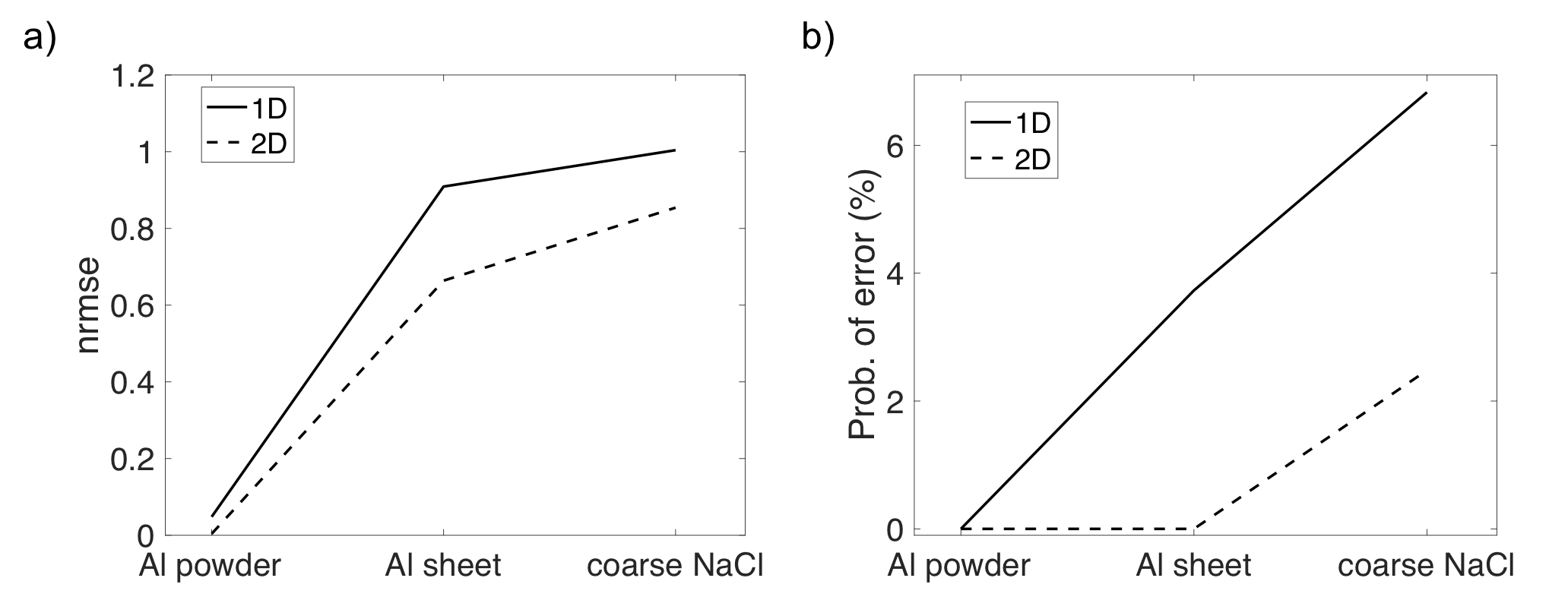

A number of studies of XRDT systems have been performed. However, to the best of our knowledge, no study of the impact of texturing has even been performed at a system level. By combining our ED Laue database and our simulation framework, we have studied the performance of XRDT systems as a function of a number of parameters, including degree of texturing, system architecture, detector parameters, etc. The figure below shows the imaging performance (left) and classification performance (right) for aluminum powder (untextured), aluminum sheet (sheet textured) and coarse grain salt (highly textured) as measured in a coded aperture XRDT system. While it is clear that texturing negatively impacts the system performance, these effects can be mitigated by collecting more of the total scatter signal (using 2D, energy-sensitive detectors). This capability is critical for accurate assessment of XRDT performance, as both clutter and threats present with a variety of types and degrees of texturing.

References

- Bi Zhao, Joel A. Greenberg, “Application of machine learning to x-ray diffraction-based classification” Proc. SPIE 1063204, Anomaly Detection and Imaging with X-Rays (ADIX) III (2018)

- Joel A. Greenberg, Chris MacGibbon, Dean Hazineh, Jesse Yue, Brian Keohane, Scott Wolter, “The role of texturing in x-ray diffraction tomography”, Proc. SPIE 1063210, Anomaly Detection and Imaging with X-Rays (ADIX) III (2018)

- Siyang Yuan, Scott Wolter, and Joel A. Greenberg, Material-identication-free detection based on material science-informed clustering Proc. SPIE 10187, Anomaly Detection and Imaging with X-Rays (ADIX) II, 101870K (May 1, 2017); doi:10.1117/12.2262942.