|

Development of an Enhanced Base Component

for the Brookhaven Atmospheric Tracer Sampler

|

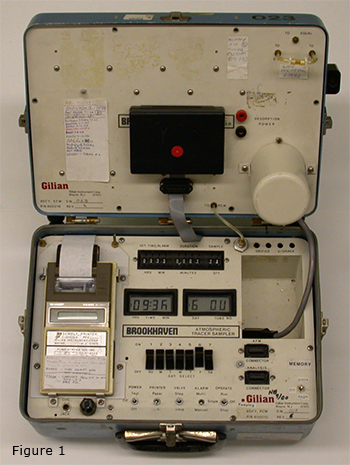

The Brookhaven Atmospheric Tracer Sampler (BATS) is an integral part of the Perfluorocarbon Tracer Technology (PFT) developed at Brookhaven National Laboratory.

The BATS is used to actively sample released PFT by pumping air through adsorbent filled tubes.

It is comprised of two components: the lid, which contains the adsorbent tubes, and the base, which contains the pump and electronic control systems.

Although the BATS lids are still state of the art, the electronic logic within the bases has become outdated over the past 20 years.

The bases lack programmability and are prone to failure in the field.

The main goal of this internship was to design a cost-effective replacement base with complete flexibility in terms of sampling periods as well as programmability through a wireless interface.

The Netburner 5272 processor board was selected for its speed, data capacity, and also its easy-to-use TCP/IP interface with an available 802.11b wireless expansion card.

This device was programmed to serve a dynamic web page and allow sample periods, the real time clock, and other settings to be programmed simply by navigating the website and filling out forms.

The pumping system was also replaced with a miniature diaphragm pump paired with a flow meter to allow the Netburner to implement a feedback controller.

This allows for precise volumes to be sampled. A working prototype was constructed with a new pump, flow meter, and processor.

|

Figure 1: The original BATS unit.

|

|

Almost every design constraint was met and the prototype includes functioning wireless programming, backup data storage, and a pumping system controlled through a negative feedback loop.

Although the prototype demonstrates proof-of-concept of the improved base unit, more work still needs to be done.

A new L-shaped circuit board needs to be designed to allow for more battery space.

This board also needs several modifications such as a more efficient power regulator and more accurate voltage reference for the flow meters.

|

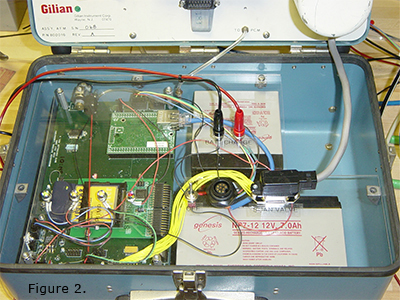

Figure 2: The prototype setup including the Netburner 5272 processor board (A), wifi expansion card (B), miniature diaphragm pump (C), and batteries (D).

|

Figure 2. shows a fully functional improved BATS prototype. The circuit board on the new unit takes up about half as much space as the previous design. This is due to advancements in electronic devices as well as the fact that the new BATS has no dials or switches to program it. It needs any computer with a web browser to program it through an ethernet cable or wireless internet.

One issue with the prototype is that the range of the wireless card is inhibited due to interference from the adjacent circuit board. This will be fixed in the future by mounting the card vertically through a hole in the front panel.

|

|

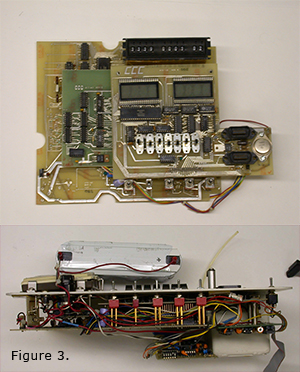

Figure 3: Two views of the original BATS electronics.

|

|

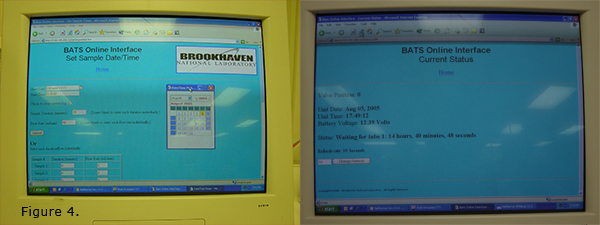

Figure 4: Two views of the graphical user interface.

|

|

Figure 4. shows two web pages which would be used during a normal tracer release experiment. The first page has several forms used to input parameters such as the start date and time of the sampling period, sample length, and flow rate. The old unit could only take one sample after another with a constant flow rate whereas the new device has no such limitations. It is also possible to reprogram the device in the middle of an experiment without affecting air samples already collected.

The second web page shown is used to examine the status of a unit that is already deployed. This page updates itself automatically and displays information such as the current time, battery voltage, and which tube the device is currently sampling on. This information is also saved several times to non-volatile flash memory during the course of an experiment.

|

|

Acknowledgements:

There are many people who made this internship an interesting, rewarding, and fun experience for me.

I am very thankful for my mentor, Ray Edwards, whose experience, circuit board design skills, and debugging ability turned this prototype into a functional device.

I also want to thank the SULI staff for running a very good program with lots of interesting events.

Finally I would like to thank Scott Smith and Mike Reynolds for letting me get involved with some "hands-on" work with the SODAR unit and all of the cinder blocks that anchor it.

Copyright © 2005 –

All Rights Reserved

|